iFixCompressors app for iPhone and iPad

Developer: Michael Diehl

First release : 06 Jun 2014

App size: 5.8 Mb

A technician can only be as good as their tools. Today, mobile devices are quickly joining the ranks of the flashlight as tools always by the technician’s side. The mobile device, with it’s instant access to a world of information, can at times be cumbersome. Scattered sources of information can leave you wondering where that important chart or formula went, iFixCompressors aims to solve this problem.

Market demand for improved efficiency and integration has brought increasingly complex compressors. By utilizing microprocessor controls and variable speed drives, compressor system have improved but they have also added to requirements placed on the technician. In order to be effective a technician needs to keep a mountain of cheat sheets, spread sheets, PDFs and paper manuals close at hand.

Today’s technician needs a tool that is technologically on par with the compressors that they service. By developing a tool tailored to the technician’s need, we can improve the efficiency and accuracy through technology. iFixCompressors is this technology. Our goal is to eliminate those clunky spread sheets and paper charts.

Notable Features:

•Controller password journal that can be exported and emailed to other users. Controllers can also be tagged by location with easy access to nearby controllers by using the Today View widget.

•Altitude correction for calculations that can be corrected. Correction can be handled automatically with GPS, Barometer (on supported devices) or a manual altitude or ambient pressure can be entered.

•Support for both U.S. Customary and SI units

•The best default unit types are determined based on the user’s Locale setting for their device at the time of first launch.

•Operating Temperature, calculate the minimum operating temperature of an oil flooded screw based on site conditions.

•Quick Conversions, quickly convert pressures, temperatures, flow rates etc.

•Leak Rate, calculate the leak rate of a system based on system capacity and pressure decay time.

•Oil Aging, calculate the effects of operating temperature on oil life.

•Maintenance Schedule, recommended maintenance items sourced from the Compressed Air Challenge.

•Glossary, terms used often in the industry.

•Electrical Symbols, common electrical schematic symbols.

•Motor FLA chart, motor full load current based on data in the NEC table 430.250

•Galvanic Corrosion chart, determine the galvanic corrosion risks of different metals.

•Pipe Properties chart, various data on pipe including ID, OD, internal volume etc.

•4-20mA Scaling, determine a scaled value from the Min and Max values of a sensor and its current mA output or determine the mA output expected based on a relative value.

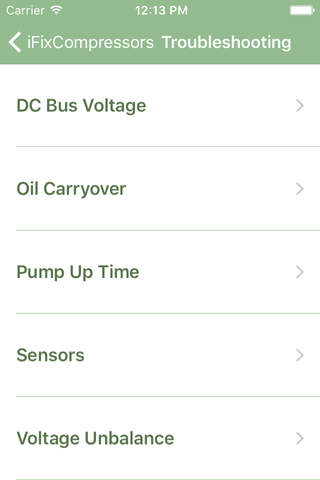

•DC Bus Voltage, determine the expected DC Bus Voltage of a VFD based on line voltage or determine expected line voltage based on measure DC Bus Voltage.

•NTC Thermistor, calculate to and from temperature and resistance of an NTC thermistor of 1K, 3K, 5K and 10K types.

•Oil Carryover, determine the expected Oil Loss based on compressor specifications and run time or determine the oil carryover density (in PPM) based on the Oil Loss volume.

•Platinum RTD, calculate to and from temperature and resistance of an RTD of PT100 and PT1000 types.

•Pressure Transducers,convert to and from pressure and voltage for pressure transducers (Gardner Denver transducers currently supported, more to be added)

•Pump Time, determine the time required to pump a system capacity from one pressure to another based on the flow rate of the compressor. A stopwatch feature is included that calculates the flow rate based on the running time.